By now, you should be very familiar with our project truck that we call Project F-Word. We have grand plans for this ’69 F100, which includes a complete build and occasional autocrossing, and maybe a few runs down the dragstrip as well. Today’s installment was long-anticipated and fun; dropping in the Gen3 Ford Performance Aluminator crate engine (M-6007-A50NAB) and Tremec T-56 Magnum 6-speed transmission. This is a pretty straightforward drop-in installation if you use all the necessary parts, most of which are available from Ford itself.

Project F Word as it sits, after the Coyote Aluminator was installed but before it was all wrapped up. This is gonna be fun!

We wanted a Coyote engine in this project because we love the high-revving nature and performance that it delivers. We plan to drive this truck hard as we said in the opening paragraph, which prompted the call for Ford’s most popular crate motor. This isn’t just an engine that has been pulled from a wrecked 2020 Mustang, it’s called the Aluminator—read all about it here.

Once unboxed, the GEN3 Coyote 5.0L crate motor is nice and shiny. This is always better than spending an hour de-crudding an original engine. More powerful and far more reliable too.

A nice touch to the crate motor is that they are each hand-assembled and signed—this one was screwed together by Robert Garcia.

We were lucky enough to be able to place an early order with Ford Performance for its new Gen3 Aluminator, so lucky that it turned out we received serial number 001. When we ordered our engine from Ford Performance we also ordered some parts that we knew we would need to get the engine in the truck and running, and allow this to go in the truck easily and make everything fit and work.

The big-box hides the crate motor and the smaller box on top is the Control Pack, which is essentially the ECU, wiring harness, and drive-by-wire throttle pedal that makes it all a no-brainer to install the engine in a non-computer-controlled vehicle, like our 1969 F100 pickup.

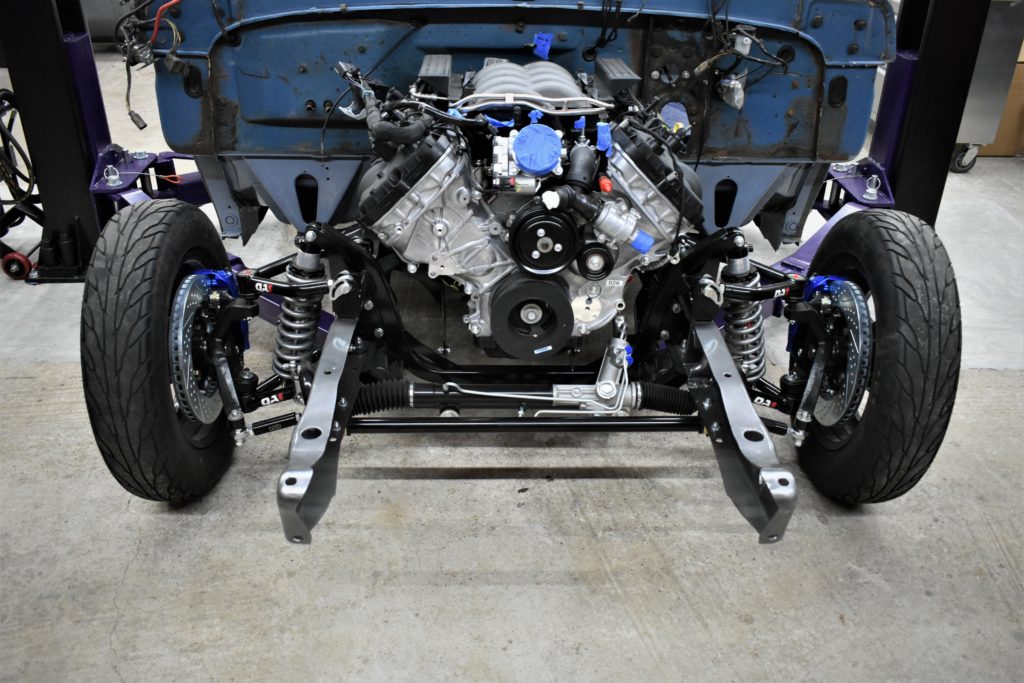

Since our truck was just a bare frame with QA1 front suspension at this point it was very easy to set the engine in. But first, we needed to remove the factory Mustang oil filter housing, which fits the new Mustang just fine but does not clear much older chassis, so we had to install the Ford Performance Oil Filter Adapter Kit. We needed the additional clearance and with the factory housing, the oil filter would not clear the QA1 crossmember. It’s important to note that the adapter does not use the factory oil bypass solenoid that is normally mounted on the factory filter housing. The good news is that our Control Pack ECU doesn’t require this signal to function properly.

To mount the engine to our chassis (which is stock but upgraded with QA1 suspension) we used Energy Suspension motor and transmission mounts (PN 4.1127G and 4.1104g respectively). These were designed to accept the ‘99-‘04 Mustang V8-specific engine mounts.

Once we had the oil filter adapter mounted to the block we could install our Energy Suspension motor and transmission mounts and drop the combo between the frame rails. The QA1 engine mounts were designed to accept the ‘99-‘04 Mustang V8 specific engine mounts and here is what we ordered.

Click this link to continue reading the full build at Ford Muscle: https://www.fordmuscle.com/tech-stories/engine/project-f-word-dropping-the-coyote-5-0l-engine/

Swapping out 2016 M GT over to 1966 F100 with Qa1 front end.

Would like to use the Brembo brakes off of the mustang but Qa1 has camaro spindles.